Our software doesn’t just connect your film logistics to your ERP system. It automatically prints a Barcode Label after each conversion.

The use of labels ensures that you know exactly how much of the rest is left over on the master rolls and helps avoid errors during customer roll dispatch. Ultimately, this leads to less material waste, fewer replacement deliveries to customers and helps with inventory-keeping.

Label printing – the possibilities

As a rule, a copy of both, the warehouse and the customer label, are printed after each order. The number of labels can be changed. If, for example, a roll is to be stored in a cardboard box, it makes sense to print two labels so that the information about the remaining length of the film is visible on the film itself and also on the cardboard outside. It could just as well be the case that you want two copies of the customer label, for example to seal the roll with one label and stick a second inside the core or on the delivery note.

A further setting can be used to control whether the quantity within an order should be ignored and a label only be printed once for the entire order. This is particularly useful for sheet cutting. When producing 100 sheets, one doesn’t require 100 labels to be produced, but rather just one for the entire order. The label printing can be paused completely. And vice versa: Even if an order has not been carried out, the label can be printed manually at any time.

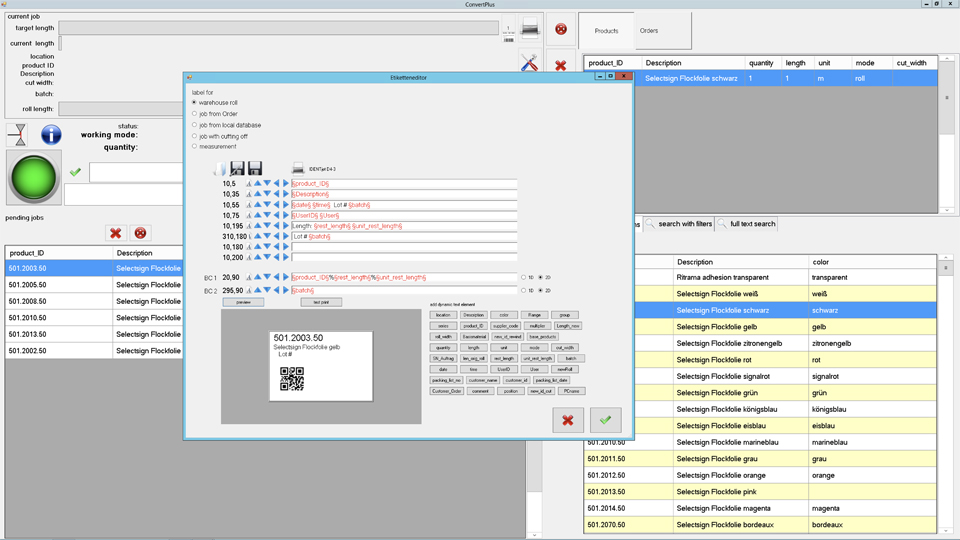

The label editor

The labels can be freely configured and designed in ConvertPlus2. There are a total of five different label designs for the different operating modes as well as storage roll or customer roll. The editor allows for individual functions to be added via buttons and to be supplemented with text. The font and size can be selected from the system fonts. You can set how far lines should be indented at the top and left, and a barcode field is freely available. It can be provided with a 1D or 2D code of arbitrary content.